Machine Tool Data Made Easy to Access, Analyze & Optimize

From fixture positions to inspection data results, recording and displaying data from your machines has never been easier. Instant access to quality and functional machine tool data means safer, streamlined management of multiple machines as well as consistent, QC reporting for customer requirements.

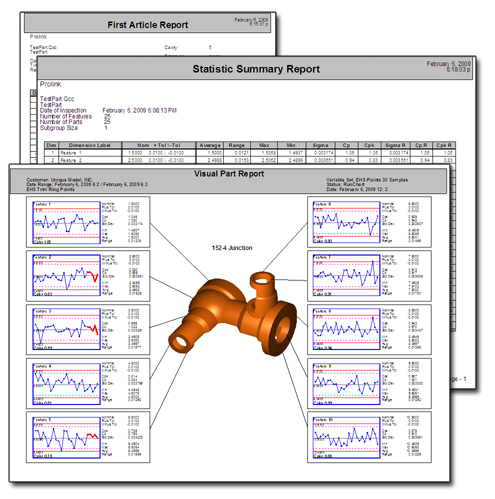

PQI combines the connectivity of MTGage, our proprietary CNC data collection software, with QC-CALC RealTime™ display to plot information in simple to read and understand charts.

How Does MTGage Work?

Data on the performance of your CNC lies within the machine tool in the form of unreadable numbers. A spindle probe measures the performance of the CNC, pulls the data and saves it internally as variable tables. MTGage macros direct the machine tool to output the store data to QC-CALC to then interpret and display in a usable form.

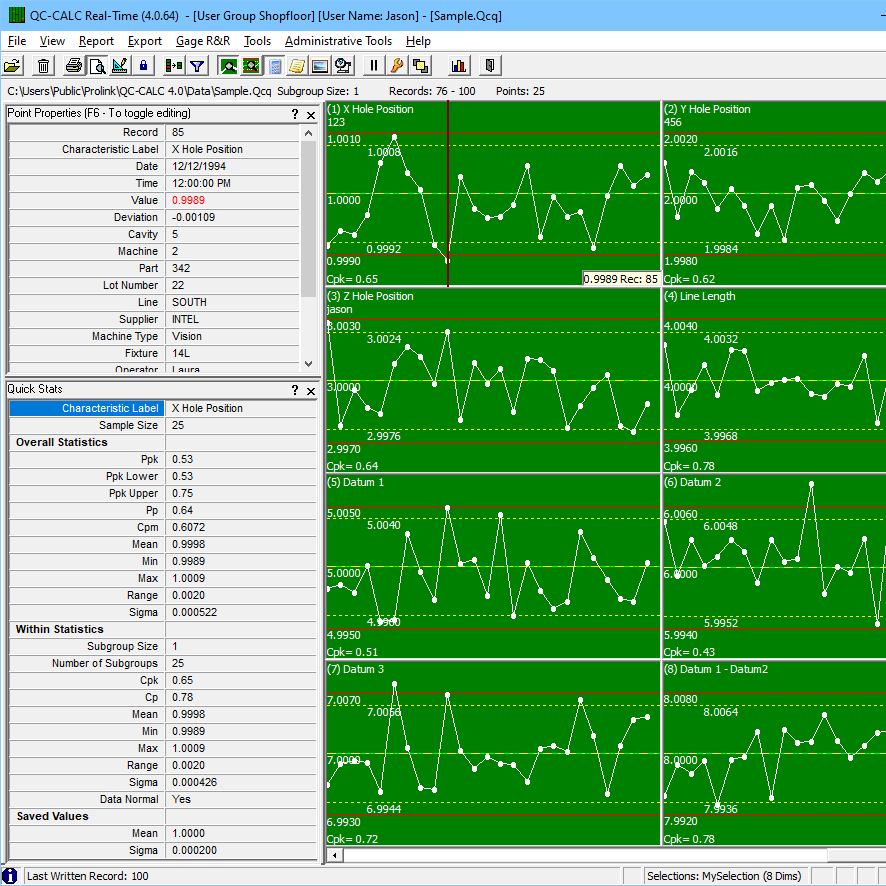

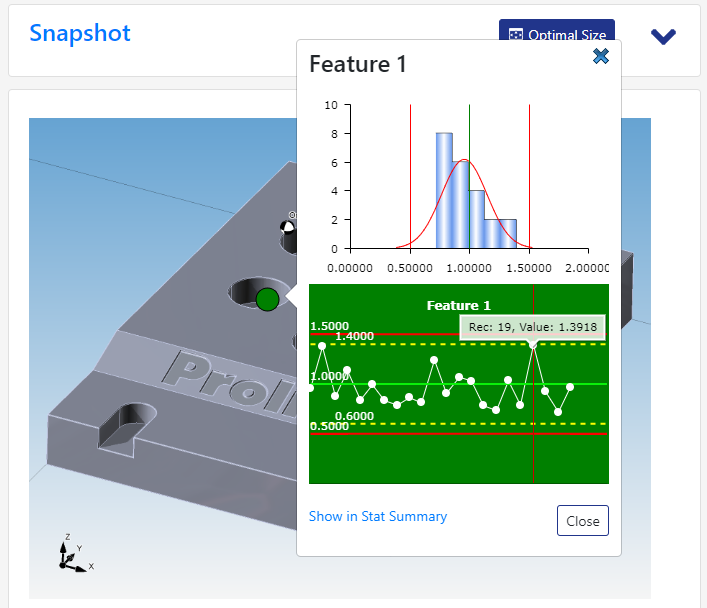

QC-CALC: Data Made Usable

QC-CALC Real-Time is used to collect and display measurement results from all CMMs, Video CMMs, and hand gages without operator intervention. You can create reports and export data to spreadsheets, databases, and other SPC programs. This means you can transfer data from all of your measurement devices to any SPC package using one program.

PQI’s Data Collection Package includes the power of QC-CALC Real-Time for display. It can be customized upon request for additional throughput, dashboards, Minitab or SPC analysis options.

Configurations for All Needs

From monitoring a single feature on a single machine to managing the data of the entire plant, PQI can provide the level of data collection that meets your management, budget, and customer reporting requirements. PQI Data Collection Packages begin with 1 MTGage license, 1 QC-CALC RealTime license, full installation and training.

One Machine Tool, One PC Display

BEST FOR

Simplifying multi-machine tool operation by machinist.

Expandable

Fast implementation

Consistent real-time visibility

Multiple Machine Tools, One PC Display

BEST FOR

Historical data capture and part qualification reports.

Fewer licenses & monitors

Reduced real-time visibility

Multiple Machine Tools, Multiple PC Displays, Multiple Outputs

BEST FOR

More robust, customized solutions.

CMM

GageStation

Network wide real-time monitoring

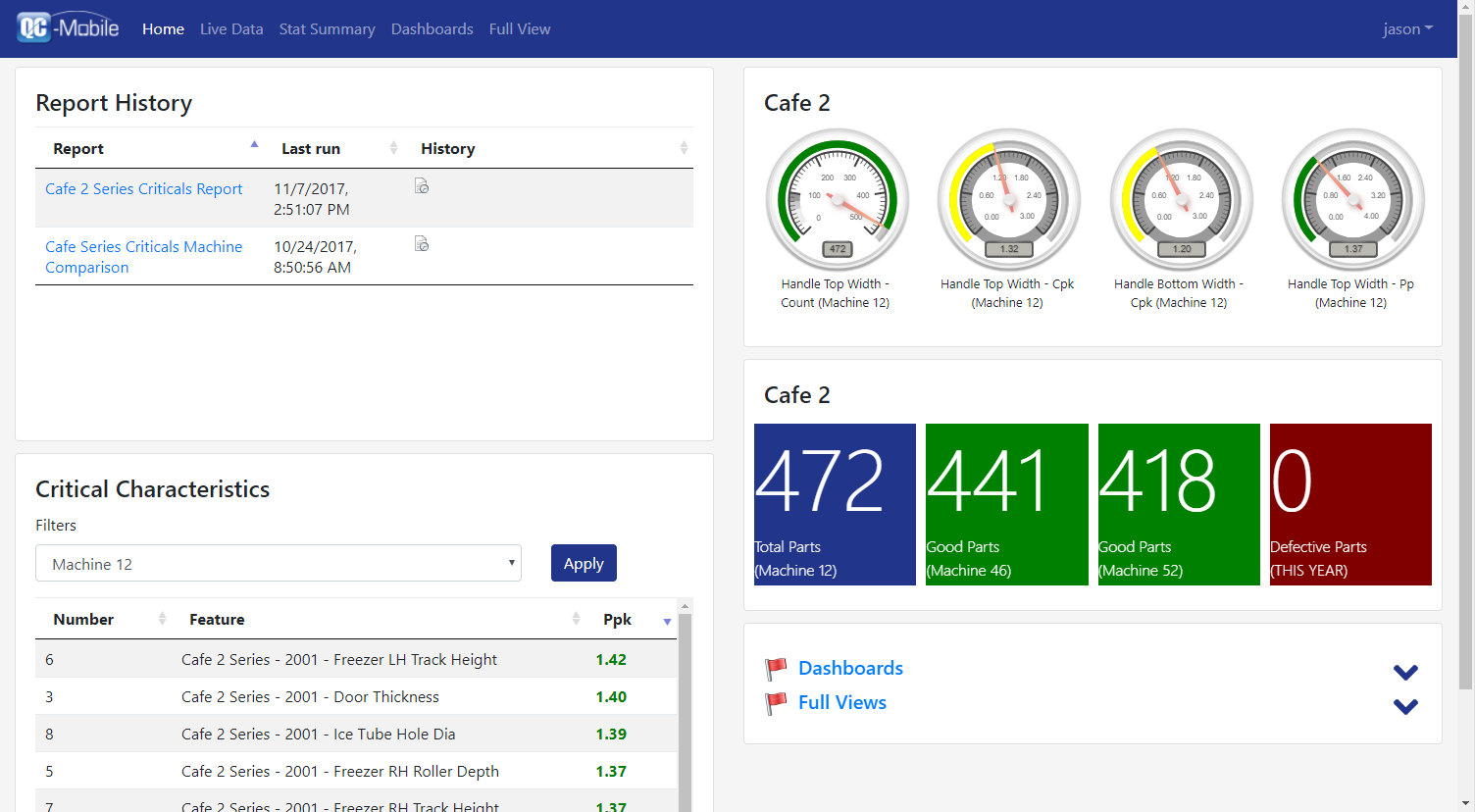

Data You Can Use… Immediately

After collection and plotting your machine tool data, you can analyze it, filter it, or generate reports via other programs for analysis:

MS Excel, MS SQL Server, Minitab, and other options are available

Send emails when exceptions are detected

Add Enterprise Report Scheduler to generate graphic displays and regular report generation