Whether you are looking to repair or upgrade, PQI can provide you with the hardware and software upgrade services that best fit your needs.

If you need immediate assistance from Machine Tool Support, please call (763) 249-8135.

The PQI Difference

No one comes close in providing individualized, qualified engineering advice one-on-one for clients during and after installation. You’ll work with a key engineer dedicated to your project throughout selection, installation and training.

0

0

0

Industries

Electrical

Aerospace

Medical

Automotive

Job Shop

Construction

Oil & Gas

Semiconductor

Hardware vs. Software Upgrades

Do you need a hardware or a software upgrade?

If you need a hardware upgrade, you may have an older version of our laser tool setters. Click here for a list of probes no longer supported.

Help us identify opportunities to cut seconds out of your processes. Do you need maintenance on your system? Are you in the know about the speed and efficiency of our latest spindle probe software?

Are you looking for integration consistency by purchasing and upgrading to an all new system?

Software Upgrade Options to Maximize Production

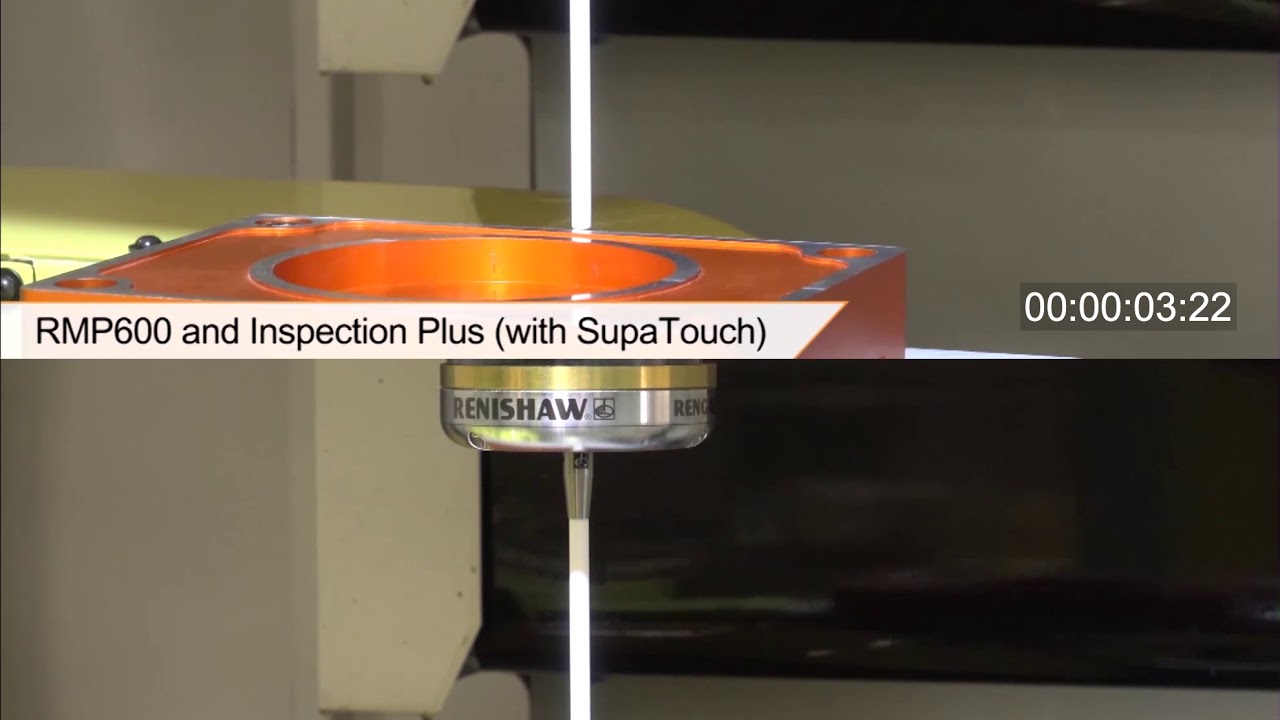

Inspection plus with Supatouch Optimization:

Our newest level of software, with the best in optimization cycle technology. This will allow the probe to run at the fastest feed-rate possible, while still maintaining repeatability.

Renishaw’s latest software can assist in high production with speed and efficiency.

PQI, ATLM Laser In-Retract

Decrease your measurement cycle times with this system. Other benefits include:

Vastly improved drip rejection - more robust in coolant

Higher, better measurement repeatability

New cycles including theoretical point and disc measurements

New Renishaw cycle for measuring oversized tools on fixed systems

New broken tool cycle

New corner radius measurement

Improved cycles, ie cutting edge checks