Resources

Case Study: Taking In-process Tool Inspection to the Next Level

To the human eye, a .125 drill bit and a .110 drill bit are almost indistinguishable. With thousands of tools in a manufacturing facility, it is very easy to get tool sizes mixed up and using an incorrect diameter tool can lead to scrapping a several thousand dollar part.

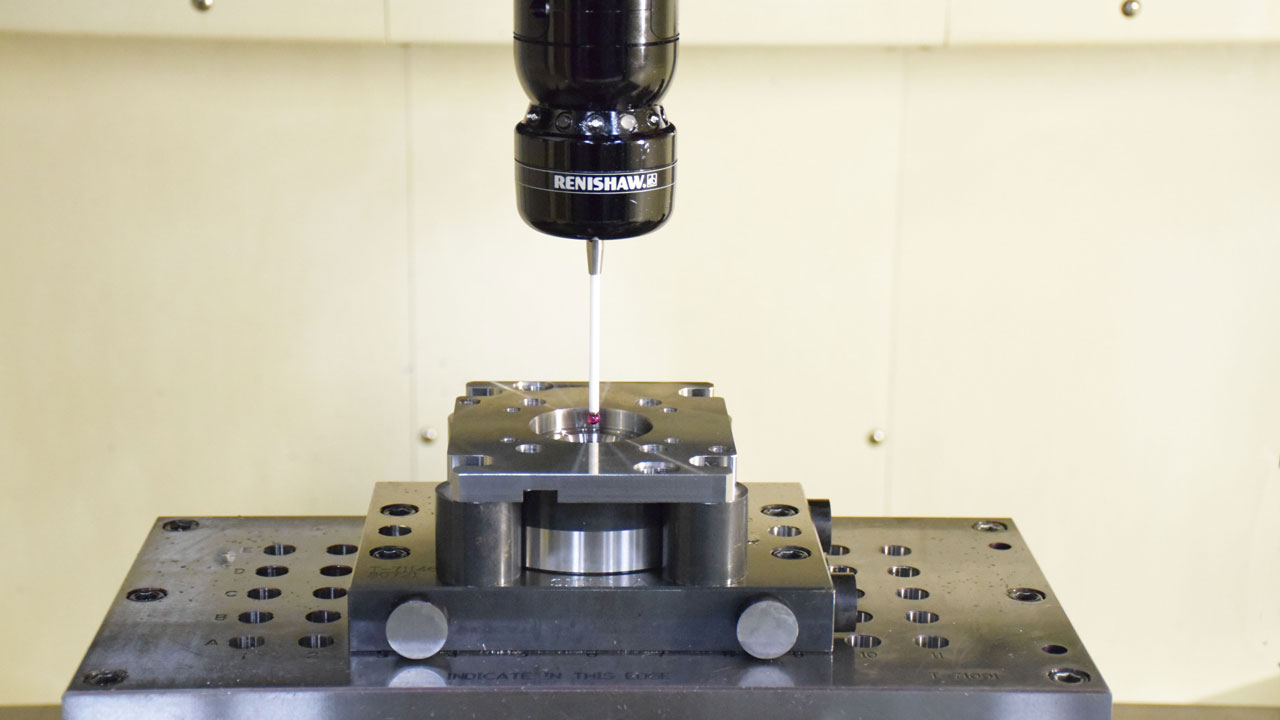

Case Study: In Process Measurement for Precision Turning

Medical devices are constantly getting smaller and tolerances tighter. The use of 5 axis swiss turning machines is a common solution for these challenges. Tolerances are often only a few ten thousands of an inch and maintaining a process capable of continuously meeting these tolerances is key.

Case Study: Von Ruden

Resources Machine Tool Metrology: Using Probe Data for In Process Checks Two long held beliefs about inspection probing on a machine tool are: “When you’re probing, you’re not making chips and when you’re not making chips, you’re not making money”. And: “Using probe data for QA checks is like having the fox watch the chicken…